How to choose a passenger&cargo ferryboat?

The river vehicle ferry is a waterborne transportation vehicle that connects the two banks and serves both vehicles (such as cars and motorcycles) and passengers. Its selection and design need to closely integrate with the waterway conditions, transportation demands, safety regulations, and operational environment, while also considering economic efficiency and comfort. The following provides a systematic explanation from three aspects: selection logic, design key points, and critical precautions.

I. Selection Logic and Core Parameters of River Vehicle Passenger Ferry

(1) Demand Analysis Before Model Selection

The selection process should be based on two core inputs: transportation demand and waterway conditions. The following key parameters need to be clearly defined:

1. Transportation demand:

• Daily/peak-hour passenger and vehicle flow (for example, for small ferries: 50-200 trips per day, for large ferries: 500-2000 trips per day);

• Vehicle type (compact car / large bus / truck, please specify the height limit and weight limit);

The number of passengers (must meet the "passenger capacity" requirements stipulated in the "Technical Rules for the Legal Inspection of Inland Vessels", usually calculated based on a standing area of 1.0 - 1.2 square meters per person).

2. Navigation conditions:

• Navigation class (such as Class I - Class VII), which affects the size of the vessel and the power of the main engine;

• Hydrological conditions (water depth, flow velocity, water level fluctuation, such as water depth ≥ 2.5m during the dry season, and flow velocity ≤ 3m/s during the flood season);

• The width of the channel and the radius of curvature (affecting the length and maneuverability of the ferry, for example, in narrow channels, the length of the vessel should be ≤ 30 meters, and the radius of curvature should be ≥ 1.5 times the length of the vessel);

• Meteorological conditions (wind speed, visibility, etc. For rivers with strong winds, the stability design needs to be strengthened).

(2) Ship Type Selection (Core Decision Point)

According to the waterway conditions and transportation demands, the common types of passenger-cargo ferries include:

Ship shape Characteristics Application scenarios

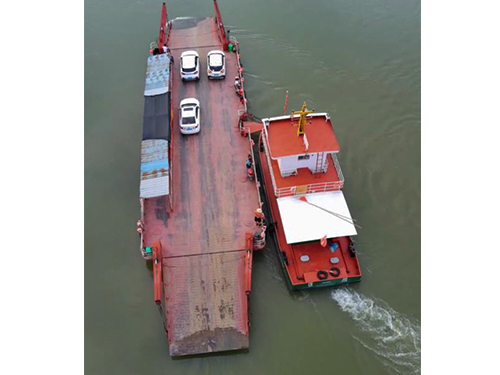

Barge-type ferries are unmanned and are towed by tugboats or shore-based power; they have a simple structure and low cost; they require accompanying mooring facilities at the dock. They are suitable for short-distance ferry services in areas with large water level fluctuations (such as seasonal rivers), with fixed routes and a small transportation volume (≤ 200 trips per day).

Motorized ferry: Self-powered (using diesel engines or electric propulsion); capable of autonomous navigation; the maneuverability and the width of the channel need to be matched. Suitable for wide channels (≥50m), with small water level fluctuations (≤2m), and routes that require frequent往返 (such as urban river-crossing transportation).

Roll-on/roll-off ferries are equipped with dedicated vehicle decks (multiple levels), gangways and securing devices; they have high vehicle loading efficiency (small area occupied per vehicle); they have high stability requirements. They are mainly used for transporting large vehicles (such as trucks and buses), and the water depth of the channel is sufficient (≥4m), with the need for rapid loading and unloading for medium and long-distance ferry transportation.

Double-hull/multi-hull ferries have a wide hull shape, good stability; large deck area; strong resistance to wind and waves; however, they are more expensive. Large ferries that operate in windy and turbulent rivers (such as those in mountainous areas) and those that need to balance passenger comfort and vehicle loading (with a capacity of ≥ 500 vehicle trips per day).

Selection suggestions:

• For small-scale short-distance ferry services (with a daily vehicle flow of ≤ 200 trips and narrow waterways): It is recommended to choose the barge-type (lower cost and simpler maintenance);

• Urban cross-river commuting (with a daily traffic volume of 200-500 vehicles, and a wide waterway): Choose the motorboat type (autonomous navigation, high flexibility);

• Large-scale vehicle transportation (mainly trucks and buses, with water depth of the channel ≥ 4 meters): Choose roll-on/roll-off ships (high vehicle loading efficiency and strong safety).

• Waters with strong winds and waves (such as mountainous river areas): Choose catamaran or multi-hull ferries (with good stability and strong wind resistance).

(III) Selection of Main Engine and Propulsion System

The power of the main engine and the propulsion method directly affect the navigation performance (speed and maneuverability) and energy consumption of the ferry. The selection should be based on the speed requirements (for inland ferries, the designed speed is usually 10-15 km/h), the carrying capacity (total tonnage), and the waterway conditions (such as in the downstream sections, higher power is required).

Propulsion method Characteristics Applicable scenarios

Diesel engine propulsion is mature and has low costs; it requires a fuel tank and an exhaust system; it generates considerable noise and vibration. Suitable for small and medium-sized ferries (with a gross tonnage of ≤ 1000) and routes with straight channels.

Electric propulsion offers continuous speed adjustment, low noise, and high efficiency (10%-15% higher than diesel engines); it requires a generator and energy storage devices (such as lithium batteries). Urban landscape routes (requiring low noise) and short-distance ferries with frequent starts and stops (such as ferry terminals spaced no more than 2 km apart).

Hybrid propulsion (diesel-electric) Diesel engine + electric motor drive; combining the high power of the diesel engine with the speed regulation advantage of the electric motor; suitable for complex conditions (such as countercurrent + frequent start-stop). Medium-sized roll-on/roll-off ferries (500 - 2000 gross tons), routes with slope in the waterway (such as the upper and middle reaches of the Yangtze River).

Key parameter calculation:

The power of the main unit needs to meet the following requirements: P = \frac{(F \cdot v)}{\eta}

Here: F represents the total resistance (kN, including frictional resistance and wave-making resistance); v represents the designed speed (m/s); η represents the propulsion efficiency (for diesel propulsion ≈ 0.7 - 0.8, for electric propulsion ≈ 0.85 - 0.9).

II. Key Design Points of River Vehicle Passenger Ferry

(1) Overall Design

1. Determination of main dimensions:

• Length (L): Determined based on the number of vehicles carried and the width of the channel (for a small ferry carrying 50 vehicles, L ≈ 30 - 40 meters; for a large ferry carrying 200 vehicles, L ≈ 60 - 80 meters); it must meet the minimum turning radius requirement of the channel (R ≥ 1.5L).

• Ship Width (B): It should meet the width of the vehicle deck (single lane ≥ 3.5m, double lane ≥ 7m) + safety passage (each side ≥ 0.8m); at the same time, stability requirements (B/T ≥ 2.5, where T is the draft) should also be considered.

• Draft (T): Must meet the freeboard height (≥0.8m, does not touch the bottom during low water period) + vehicle deck height (≥1.2m, prevents water accumulation).

2. Linear Design:

• Utilizes a bulbous bow (reduces wave-making resistance and increases speed);

The stern is equipped with a stern fin (to enhance the efficiency of the propeller and reduce cavitation);

The ship is equipped with a roof (to protect from rain and snow and enhance passenger comfort);

The vehicle deck should have a longitudinal inclination of no more than 1° (to prevent the vehicle from sliding).

(II) Structural Design

1. Ship body material:

• The mainstream choice is steel for the ship body (high strength, resistant to collisions, accounting for over 90% of inland ferries);

• Small ferries can be made of aluminum alloy (which is lightweight, reduces energy consumption, but has high cost and is prone to corrosion).

• The key areas (the bow and stern compartments, the engine room) need to be reinforced with thick steel plates (≥ 8mm), and the anti-collision capacity should be ≥ 50cm (in accordance with the regulations for inland waterways).

2. Sections and Strength:

• Divide the main transverse bulkheads according to the "Technical Rules for the Legal Inspection of Inland Ships" (at least 3 bulkheads, divided into the bow and stern compartments, engine room, cargo/passenger compartments, and stern and bow compartments);

The vehicle deck should be equipped with longitudinal bulkheads (one every 5-8 meters) to prevent damage to the hull and water ingress in case of vehicle collision.

Calculate the total longitudinal strength (the combination of wave bending moment and static water bending moment), and ensure that the ship's deflection is ≤ L/1000 (where L is the ship's length).

3. Vehicle Loading Design:

• Platform: Utilizes a hydraulic folding type (length ≥ 6m, width ≥ 3m), with a slope ≤ 1:8 (to prevent vehicle sliding); Anti-collision guardrails (made of rubber or polyurethane) must be installed.

• Anchoring device: Grounding bells are installed on the vehicle deck (spacing ≤ 2m), and chains/steel ropes (breaking force ≥ 10 tons) are used to prevent the vehicle from sliding.

• Area Management: Divide the area according to vehicle types (small vehicle area, large vehicle area). Heavy vehicles (trucks) should be placed in the lower position of the ship (to lower the center of gravity).

(III) Safety System Design

1. Life-saving and Firefighting:

• Life-saving equipment: Provide life jackets in accordance with the passenger capacity at 100% (child-specific life jackets ≥ 10%), and each deck should have at least 2 lifeboats (≥ 30 people);

• Fire protection system: The engine room is equipped with a CO₂ fire suppression device (capacity ≥ 40% of the engine room volume), and the passenger cabin is equipped with a water mist sprinkler system (coverage area 100%).

• Fire detection equipment: Install smoke/temperature detectors (covering the entire cabin and cockpit), and set up a fire alarm monitoring screen on the bridge.

2. Navigation and Control:

• Navigation Equipment: Standard configuration includes GPS + Beidou dual-mode positioning, AIS (Automatic Identification System for Ships), radar (3GHz, detection range ≥ 10km), and VHF (Very High Frequency) communication;

• Control System: Equipped with dual rudders (one for each side of the vessel, consisting of a propeller and a steering gear), enhancing low-speed maneuverability (such as berthing and unberthing).

• Night lighting: Deck lighting ≥ 50 lx (passenger area), cabin lighting ≥ 30 lx, signal lights comply with the "Inland Navigation Collision Avoidance Rules" (red/green side lights, white stern lights).

(4) Comfort Design

Passenger cabin:

• Equipped with a closed cabin (for protection from wind and rain) and an open deck (for viewing), with a per capita area of the cabin ≥ 1.5 square meters (seat spacing ≥ 0.8 meters);

• Configure the air conditioning system (26-28℃ in summer, 18-20℃ in winter) and ensure ventilation (at least 30 times per hour).

2. Vibration and noise reduction:

• The main unit is installed with elastic components (rubber pads), and there is a soundproof partition between the engine room and the passenger cabin (sound insulation level ≥ 25 dB);

• Propeller optimization (using large angle blades), reducing underwater radiated noise (≤ 75 dB(A), ≤ 65 dB(A) inside the cabin).

(5) Environmental Protection Design

Wastewater treatment:

• Domestic sewage (black water/grey water) must be treated to meet the standards (COD ≤ 100mg/L, BOD ≤ 20mg/L) before being discharged, or stored in the sewage tank (and then discharged to the receiving facility upon arrival).

The engine room oily wastewater is treated by an oil-water separator (with an oil content of ≤ 15 ppm) before being discharged.

2. Exhaust Emission:

• Diesel engines must comply with the "Implementation Plan for Control of Air Pollutants from Inland Vessels" (NOx ≤ 3.4g/kWh, PM ≤ 0.03g/kWh);

Large ferries can be powered by LNG (reducing CO₂ emissions by ≥ 20%, with no SOx/PM emissions).

III. Key Considerations for River Car Passenger Ferries

(1) Regulatory Compliance

Comply strictly with the "Technical Rules for the Legal Inspection of Inland Waterway Vessels (2020)" and the "Regulations on the Safety Management of Inland Waterway Traffic", and undergo inspection by CCS (China Classification Society) or local ship inspection authorities.

• If crossing provincial boundaries, it is necessary to comply with regional regulations such as the "Standard Ship Dimensions Series for Through-Gate Transport Vessels on the Yangtze River Mainstream".

The vehicles being loaded must comply with the "Regulations for the Safety Supervision and Management of Dangerous Goods Carried by Inland Vessels" (for example, flammable goods need to be isolated separately).

(2) Channel Adaptability

• For the dry season (when water depth is insufficient): The draft should be ≤ the minimum water depth of the channel minus 0.5 meters (to leave a safety margin);

• For the flood season (with high flow rate): Enhance the maneuverability of the vessel (such as increasing the area ratio of the rudder), and set the flood speed limit (≤ 10 km/h);

• For curved channels: The ship's speed should be ≤ the curved radius × 0.6 (to prevent the ship from touching the shore).

(III) Operational Efficiency

• Energy consumption optimization: Utilize electric propulsion or hybrid propulsion (which can save 15%-20% of fuel compared to pure diesel engines);

• Maintenance cost: Select standardized components (such as the diesel engine brand should be favored by Cummins or Weichai), and conduct regular maintenance (the main engine should be serviced every 500 hours, and the propeller should be measured for thickness every 2 years);

• Increased passenger load factor: Through intelligent dispatching systems (such as reservation-based ticketing), the peak and off-peak passenger flows are balanced to avoid underloading.

(4) Special Situations Handling

• Low visibility (foggy days, heavy rain): Turn on radar + AIS, reduce speed (≤ 5 km/h), sound fog signal (once every 2 minutes);

• Vehicle overloading: Install weighing systems (such as scales), and prohibit overloading (more than 10% overload requires unloading);

• Passenger emergency: Quarterly conduct abandon-ship drills (rescue boat landing time ≤ 3 minutes), and set up clear escape signs (fluorescent guiding signs).

IV. Summary

The selection and design of river passenger ferry vessels should be based on the transportation requirements, waterway conditions, and safety regulations. Through the coordinated design of vessel type selection , engine matching (diesel engine/electricity/hybrid propulsion), structural optimization (division of compartments/securement/stability), and safety systems (life-saving/fire-fighting/navigation), the safety, applicability, and economy of the vessels in complex inland water environments can be ensured. In actual engineering, specific route characteristics (such as the middle reaches of the Yangtze River, the Pearl River Delta) should be considered, and standardized and modular design schemes should be given priority. Regular maintenance and intelligent management should be carried out to ensure long-term reliable operation.